In the dynamic and ever-evolving world of construction and architecture, the term "structural engineering" holds a position of paramount importance.

Introduction

Most people across the globe spend about 87 percent of their time indoors. Unfortunately, staying indoors for extended periods can have negative health repercussions, especially if the indoor air is polluted. According to the WHO (World Health Organization), contamination of indoor air due to poor ventilation causes about 1.6 million premature deaths every year.

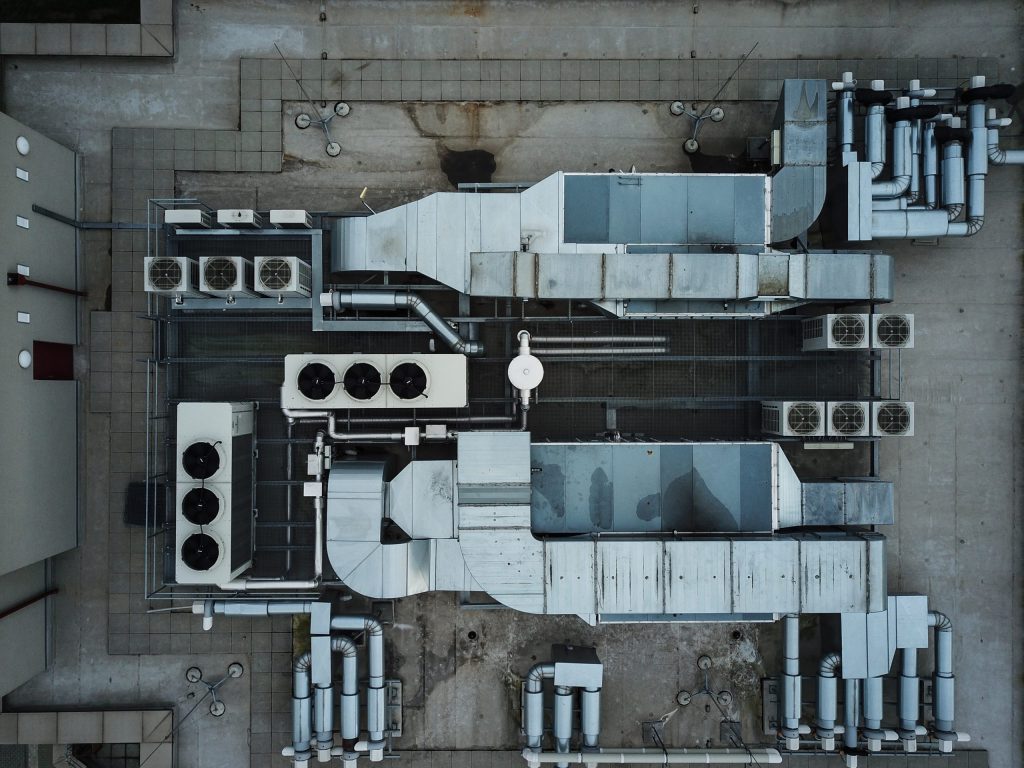

Luckily, various solutions make it possible to design buildings that are hospitable to people without impacting their health & well-being. One such solution is creating an air filtration system design that replaces indoor air with outside air at a faster rate. In addition, these systems filter air effectively, ensuring that it’s free from dangerous contaminants.

To help you get a better understanding of this topic, we’ll be looking at the basics of air filtration system design in this article. First, let’s look at the various types of contaminants that affect indoor air quality in buildings.

Types of airborne pollutants in buildings

In general, there are 3 types of pollutants found in the HVAC design of buildings. That is’ biological, gaseous, and particulate contaminants. Each type of pollutant requires a unique air treatment system design to minimize its concentration in MEP design.

Biological contaminants. Biological pollutants include fungal organisms, bacteria, and viruses. These organisms are either drawn into the facility through the HVAC unit’s fresh intake or come from within the facility.

Gaseous contaminants. These include; nitrogen oxide, sulfur dioxide, ozone, and carbon monoxide. Like biological contaminants, gaseous contaminants are mostly drawn into the buildings by the HVAC system. However, they can also come from synthetic materials within the facility like adhesives, caret as well as composite materials.

Particulate contaminants. These pollutants include; smoke, dirt, dust, and mists. More notably, they’re either drawn into the facility from outdoor air or originate from within the facility. All in all, most types of filtration systems in HVAC units are designed to minimize the concentration of particulates.

Effective Air Filtration system Design Options

Removing pollutants and ventilating the building with clean outside air are the most effective ways of improving indoor air quality. Also, studies demonstrate that filtration can be an effective way to supplement ventilation. This may include upgrading the air filtration system in your HVAC design or using a portable air purifier.

In this section, we’ll show your various effective air filtration systems you can use to remove pollutants from your building’s indoor air.

Mechanical air filters are some of the most commonly used filtration systems in facility HVAC systems. They consist of a filter media (high-loft, non-woven material or spun glass) that filters out particles through the process of impaction and straining.

Filters from varying manufacturers tend to have different efficiencies, based on their construction and design. Note, the filter’s efficiency refers to the rate at which the filter media gets rid of the airborne particles. To determine the filter’s efficiency, you can follow standard 52.2 by the ASHRAE. Any air treatment system design that is tested using this standard is given a rating number known as MERV. MERV is an acronym for Minimum Efficiency Reporting Value.

A higher MERV rating indicates that the system has a better filtration efficiency. As a drawback, this means that airflow in the filtration system will have a greater resistance as well. To overcome this resistance, the fan energy use should be increased.

That aside, mechanical filters are available in various designs depending on the requirements of the application. Surprisingly, the flat panel, which operates through the straining process, is the most commonly used filtration system design. They have a low cost and a MERV rating of 5 or less. For that, they’re ideal for use in buildings where the HVAC systems aren’t exposed to very dirty surroundings.

However, for institutional and commercial applications, you can use more expensive flat panels with an MRV rating of 5- 8. Such filters utilize a pleated filtering material to offer a larger air filtering surface.

Although mechanical filters are quite effective in removing particulate pollutants, they don’t get rid of all contaminants. For instance, they don’t have any impact on gaseous contaminants at all. Instead, removing vapors and gases that are less than 0.01 micros requires the installation of gas-phase filters.

A gas-phase system operates on the basis of adsorption. This is the process whereby liquid, gas, or dissolved solid molecules/ atoms become chemically attached to the surface. In most gas-phase systems, the surface is usually made up of activated charcoal.

In terms of application, these systems are mainly used in facilities that regularly emit fumes, chemicals, and vapors into the air within an occupied space. Also, they can be installed in buildings located near a source of air pollution.

Compared to particulate and gaseous pollutants, biological contaminants are way smaller. For that, both gas-phase filters and mechanical filters will not be effective against them. In this case, you’ll need a UV light system of proper wavelength and in sufficient doses. This will help to deactivate viruses and kill fungal & bacterial organisms within your HVAC system’s fresh air intake.

With that in mind, a UV system that emits UV-C light with 200 – 280nm wavelength is the most effective system for eliminating biological pollutants. However, the system’s effectiveness will vary depending on other factors like the velocity & volume of air, the organisms being targeted, UV-C light intensity, etc.

On the downside, direct exposure to UV-C light can cause damage to the eyes and skin to the maintenance personnel. For that reason, it’s important to take the necessary safety steps that will ensure worker safety. Also, warning signs should be posted on UV light systems to increase awareness among the workers.

Final Word

As you’ve seen, no one air filtration system will meet the requirements of every building. For that, before you choose an air filtration system, it’s good to understand the level and type of contamination in the facility first. Afterward, you can select or even combine air filtration systems that will offer the best benefit to the operation of your facility.

About Author

InnoDez