In the complex world of construction, compliance with building codes is critical to ensuring safety, functionality, and sustainability. Mechanical, Electrical,

In the dynamic world of construction and engineering, MEP (Mechanical, Electrical, and Plumbing) design plays a critical role in ensuring the functionality and sustainability of any building project. However, the process of MEP engineering goes beyond mere blueprints. It is a collaborative endeavor that involves close coordination and communication between architects, contractors, and MEP engineers, highlighting the importance of MEP Engineer Collaboration.

Understanding MEP Engineering

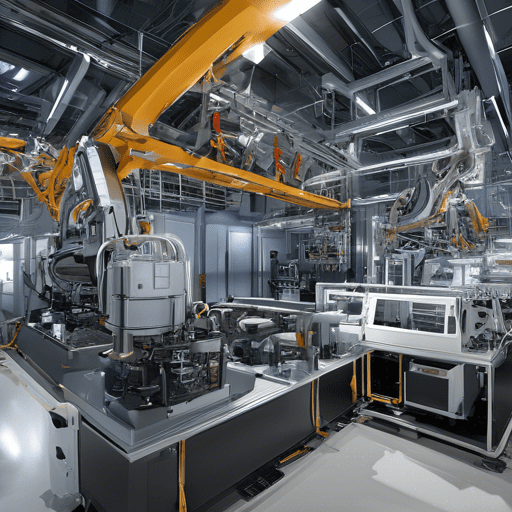

MEP engineering encompasses the design, installation, and maintenance of the mechanical, electrical, and plumbing systems in a building. These systems include heating, ventilation, air conditioning, lighting, power distribution, water supply, and drainage. The goal of MEP engineering is to create efficient, safe, and sustainable buildings that meet the needs of the occupants while adhering to local regulations and standards.

To achieve this, MEP engineers work closely with architects and contractors throughout the entire project lifecycle. This MEP Engineer Collaboration ensures that comprehensive designs integrate seamlessly with the architectural and structural elements of the building. This collaboration ensures that MEP systems are not only functional but also aesthetically pleasing and space-efficient.

The Importance of Collaboration in MEP Engineering

Collaboration is the cornerstone of successful MEP engineering projects. It is essential for ensuring that all stakeholders have a shared understanding of the project goals, requirements, and constraints. By working together, architects, contractors, and MEP engineers can identify and resolve potential issues early on, minimizing costly changes and delays during construction through effective MEP Engineer Collaboration.

Moreover, collaboration allows for the optimization of resources and the reduction of waste. Through effective communication and coordination, MEP engineers can design systems that are energy-efficient, cost-effective, and sustainable. They can leverage their expertise to recommend innovative solutions that minimize the environmental impact of the building while maximizing comfort and functionality.

The Collaborative Process in MEP Engineering

The collaborative process in MEP engineering involves a series of iterative steps, from the initial design phase to the final installation and commissioning. It begins with the gathering of project requirements and the development of a design brief. Architects and MEP engineers work closely to understand the functional and aesthetic requirements of the building, as well as any specific challenges or constraints, epitomizing MEP Engineer Collaboration.

Once the design brief is established, MEP engineers proceed to develop the initial design concept. This concept is then reviewed and refined in collaboration with architects and contractors. The goal is to ensure that the MEP systems integrate seamlessly with the architectural and structural elements of the building, without compromising on functionality or aesthetics.

After the design concept is finalized, detailed engineering drawings and specifications are prepared. These documents serve as a guide for the installation and construction teams, providing them with the necessary information to execute the project accurately. Throughout the construction phase, collaboration continues through regular meetings, site visits, and coordination efforts to address any issues that may arise, emphasizing the ongoing need for MEP Engineer Collaboration.

Key Players in the Collaborative Process

The collaborative process of MEP engineering involves several key players, each with their own expertise and responsibilities. Architects are responsible for the overall design and aesthetics of the building. They work closely with MEP engineers to ensure that the MEP systems are seamlessly integrated into the architectural design, without compromising on the visual appeal of the building.

Contractors are responsible for the construction and installation of the MEP systems. They collaborate with architects and MEP engineers to ensure that the design is implemented accurately and efficiently. Their role is crucial in coordinating the different trades involved in the installation process and ensuring that the project is delivered on time and within budget.

MEP engineers are the technical experts who design and specify the MEP systems. They collaborate with architects and contractors to ensure that the design meets the functional requirements of the building, complies with local codes and regulations, and aligns with the project budget. Their expertise in energy efficiency, sustainability, and system integration is vital for the success of MEP engineering projects.

Benefits of a Collaborative Approach in MEP Engineering

A collaborative approach in MEP engineering offers several benefits for all stakeholders involved in a construction project. By working together, architects, contractors, and MEP engineers can:

Tools and Technologies for Collaborative MEP Engineering

In today’s digital age, the collaborative process in MEP engineering is greatly facilitated by advanced tools and technologies. Building Information Modeling (BIM) software is one such tool that has revolutionized the way MEP engineers collaborate with architects and contractors. BIM allows for the creation of a virtual 3D model of the building, which integrates the architectural, structural, and MEP systems.

This virtual model serves as a central repository of project information, accessible to all stakeholders involved. It enables real-time collaboration, clash detection, and coordination between different disciplines, ensuring that the design is fully coordinated and clash-free before construction begins. BIM also facilitates the generation of accurate quantity take-offs, cost estimates, and construction schedules, streamlining the project management process, highlighting the role of MEP Engineer Collaboration.

Additionally, cloud-based collaboration platforms and project management tools enable seamless communication and document sharing among team members. These platforms provide a centralized space for stakeholders to collaborate, share updates, and track project progress. They eliminate the need for physical meetings and enable real-time collaboration, even for geographically dispersed teams.

Challenges and Solutions in Collaborative MEP Engineering

While collaboration is essential for the success of MEP engineering projects, it is not without its challenges. One of the main challenges is the coordination of multiple stakeholders with different priorities and perspectives. To overcome this challenge, clear communication channels and frequent meetings are necessary to ensure that all stakeholders are aligned and working towards a common goal through effective MEP Engineer Collaboration.

Another challenge is the integration of different design disciplines, such as architecture, structure, and MEP systems. This requires close collaboration and coordination to ensure that the design is clash-free and fully coordinated. BIM software and clash detection tools can help identify and resolve clashes early on, minimizing rework and delays during construction, further emphasizing MEP Engineer Collaboration.

Furthermore, the fast-paced nature of construction projects can pose challenges to collaboration. Strict timelines and budget constraints may limit the time available for collaboration, making it crucial for stakeholders to efficiently communicate and make decisions. Regular project meetings, clear roles and responsibilities, and effective project management can help overcome these challenges and ensure smooth collaboration.

Future Trends in Collaborative MEP Engineering

As technology continues to advance, the future of collaborative MEP engineering looks promising. Emerging trends such as augmented reality (AR), virtual reality (VR), and artificial intelligence (AI) are revolutionizing the way stakeholders collaborate and visualize MEP systems. AR and VR allow for immersive experiences, enabling stakeholders to visualize and interact with the building’s MEP systems in a virtual environment. AI-powered tools can automate repetitive tasks, such as clash detection and code compliance checks, freeing up valuable time for stakeholders to focus on more complex design challenges, enhancing MEP Engineer Collaboration.

Additionally, the integration of IoT (Internet of Things) devices in MEP systems offers new opportunities for collaboration and optimization. IoT devices can provide real-time data on energy consumption, equipment performance, and occupant comfort, allowing stakeholders to make informed decisions and continuously improve the performance of the building. This data-driven approach enhances collaboration by providing stakeholders with valuable insights and facilitating data-driven decision-making.

Conclusion

In conclusion, MEP engineering is a collaborative process that goes beyond the blueprint. By working hand in hand, architects, contractors, and MEP engineers can leverage their expertise to overcome challenges, optimize resource allocation, and deliver high-performance buildings that meet the diverse needs of clients. Effective communication channels, advanced digital tools, and a shared commitment to excellence are the keys to successful collaboration in MEP engineering, emphasizing the role of MEP Engineer Collaboration.

As the construction industry continues to evolve, collaboration will remain a vital component of MEP engineering projects. By embracing new technologies, overcoming challenges, and fostering a culture of collaboration, stakeholders can unlock the full potential of MEP engineering and create buildings that are not only functional and sustainable but also transformative in their impact. Join us as we go beyond the blueprint and explore the transformative power of collaboration in MEP engineering, with a focus on MEP Engineer Collaboration.

About Author

Xhuljo Jakup