To prevail in the present super cutthroat speedy serve eatery scene, it's fundamentally significant that brands give an enticing climate

In the bustling world of restaurant kitchens, efficient MEP engineering is crucial for maintaining a smooth operation. One aspect that often gets overlooked but is of utmost importance is the design and selection of grease traps. These vital components play a significant role in maintaining the health of your plumbing and ensuring compliance with regulations.

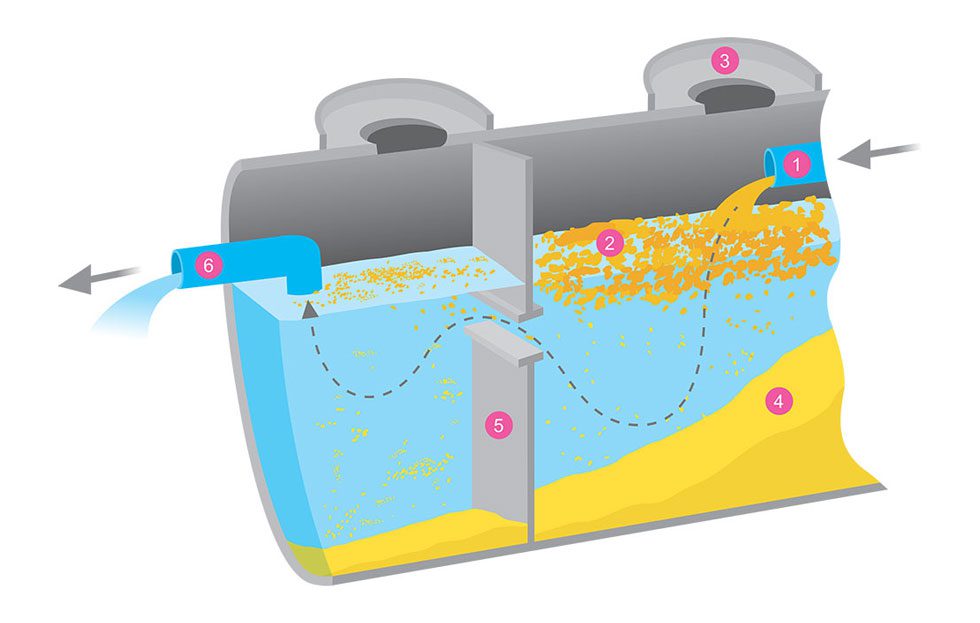

Exploring Grease Traps from an MEP Engineering Viewpoint

When it comes to grease traps, not all are created equal. Different types cater to varying kitchen setups and volumes of grease production. As MEP engineers, understanding the nuances of each type is essential for optimizing the system’s functionality.

Aligning with MEP System Requirements and Regulations

Properly integrating grease traps into your MEP system involves more than just selecting the right type. Compliance with local regulations and MEP system requirements is equally critical. Here are key aspects to consider:

Conclusion: Navigating the Greasy Waters with MEP Wisdom

In the dynamic world of restaurant MEP engineering, choosing the right grease trap involves a delicate balance between design, functionality, and regulatory compliance. MEP engineers at InnoDez understand that each kitchen is unique, requiring a tailored approach to grease trap selection and integration. By aligning with MEP system requirements and regulations, our experts ensure that your kitchen stays efficient, compliant, and free from plumbing woes.

About Author

InnoDez