Section 1: The Dynamic Duo: An Introduction to MEP - Ah, MEP! The unsung heroes of our built environment. If

Introduction

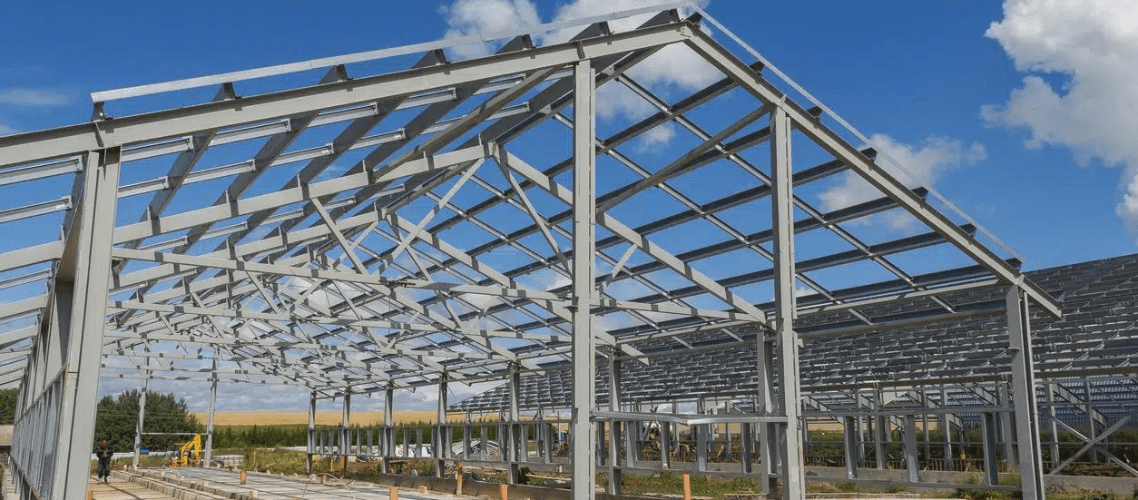

Pre-engineered metal buildings or MBS (Metal building systems) refers to proprietary structures that are manufactured and designed by their suppliers. Surprisingly, these structures are very popular in the USA. Moreover, they account for a significant proportion of low-rise non-residential structures in the country.

However, unlike the metal building systems, the foundations of these structures don’t come prepackaged. Instead, their foundations have to be properly designed and laid on-site to support the structure and prevent major problems.

Unfortunately, the foundation design for metal buildings usually involves unique challenges. Even worse, their designs are not specified in the technical design guides and building codes, making them quite difficult to understand. On the bright side, this article discusses some important aspects associated with foundation design for the structures.

So, read on to discover various foundation design options you can consider for your metal building structure!

Special challenges associated with foundation for metal buildings

Generally speaking, foundations for MBS experience different challenges from those used in conventional structures. Some of these issues include;

Common types of foundations for Metal Building structures

There are various types of foundation systems that are commonly used for metal buildings. They include;

This type of foundation for metal buildings involves tying the foundation to columns at the opposite structure columns. The construction of tie rods ranges from more reliable options like concrete grade beams to cheap options like placing reinforcing bars in a thickened slab. On the downside, tie rods are not ideal for use in structures with depressions, pits, and deep trenches.

Although this foundation system is widely used in residential buildings, it can be used to support large metal buildings as well. However, its reliability and versatility depend on whether its design is reliant on the slab on grade.

In general, the idea behind the design of hairpins with slab ties is similar to the tie-rod foundation system. However, in this case, the distributed reinforcement in the slab (slab ties) resists the tension force instead of the discrete tie rods. Surprisingly, this foundation system is the most affordable technique for resisting horizontal column reactions.

But, like any other foundation system, it suffers from various drawbacks as well. For instance, due to its reliance on the slab, it’s susceptible to the floor slab being partly removed or cut. In addition, the slabs on grade have construction joints, where the reinforcement generally stops.

Deep foundation systems can be further categorized into 2 groups. That is; piles and deep piers (drilled shafts/ caissons). Typically, deep piers have an adequate dead load to resist moderate wind uplift. But if an additional load is required, perimeter grade beams can be considered. Besides, grade beams engage the soil’s passive pressure resistance, helping the foundation resist horizontal column reactions. On the contrary, the pile can resist both horizontal and uplift forces in various ways.

All in all, deep foundations don’t rely on the floor slabs. For that reason, they’re both versatile and reliable. And although they’re costly, they’re suitable for use in poor soils.

In this type of foundation, the system depends on the weight of the soil and foundation to resist sliding and overturning due to external horizontal forces. More notably, it’s one of the most reliable foundation systems available since it doesn’t rely on slab on grade. Also, it’s very versatile since depressions, pits and deep trenches in the floor don’t impact its function. For those reasons, you can use this foundation system in hillside installation, where one part of the structure is higher than the other.

The use of mats in MBS is another incredible option for structures being installed on poor soils. In essence, mays are reinforced in 2 directions, at the bottom, and at the top. The continuous reinforcement of mats helps to solve the issue of ‘extinguishing’ horizontal column reactions at the ends of the frames. Moreover, they work well in counteracting wind uplift, especially if they’re heavyweight.

One drawback of using mats in MBS with multiple-span rigid frames though is that the interior columns require anchor bolts. Also, they have a relatively high construction cost and low versatility.

Trench footing involves excavating a deep trench and filling it with concrete. This results in a foundation system with enough weight and depth to resist uplift and develop passive soil pressure. Also, the system has high versatility and reliability since it doesn’t rely on the slab on grade’s contribution. However, this type of foundation can only be constructed in stable soils that allow trench excavation.

Final Word

Choosing the best foundation system for your MBS will depend on various factors. For instance, the decision can be influenced by the frost levels, wind speeds, soil quality as well as load levels. Also, you’ve to consider the few building codes for metal building foundations that exist.

For that, it’s important to consult as an MBS supplier or a knowledgeable local contractor to ensure the structure has an appropriate foundation. If you’re planning to build foundations for a metal building in California, feel free to contact Innodez Design & Engineering. Our professionals will handle all your construction and design needs. As a result, your metal building will have the appropriate foundation system to give it stability, longevity, and strength.

About Author

InnoDez