Welcome to the World of Building Automation and Control Systems Welcome to the world of Building Automation and Control Systems

Introduction

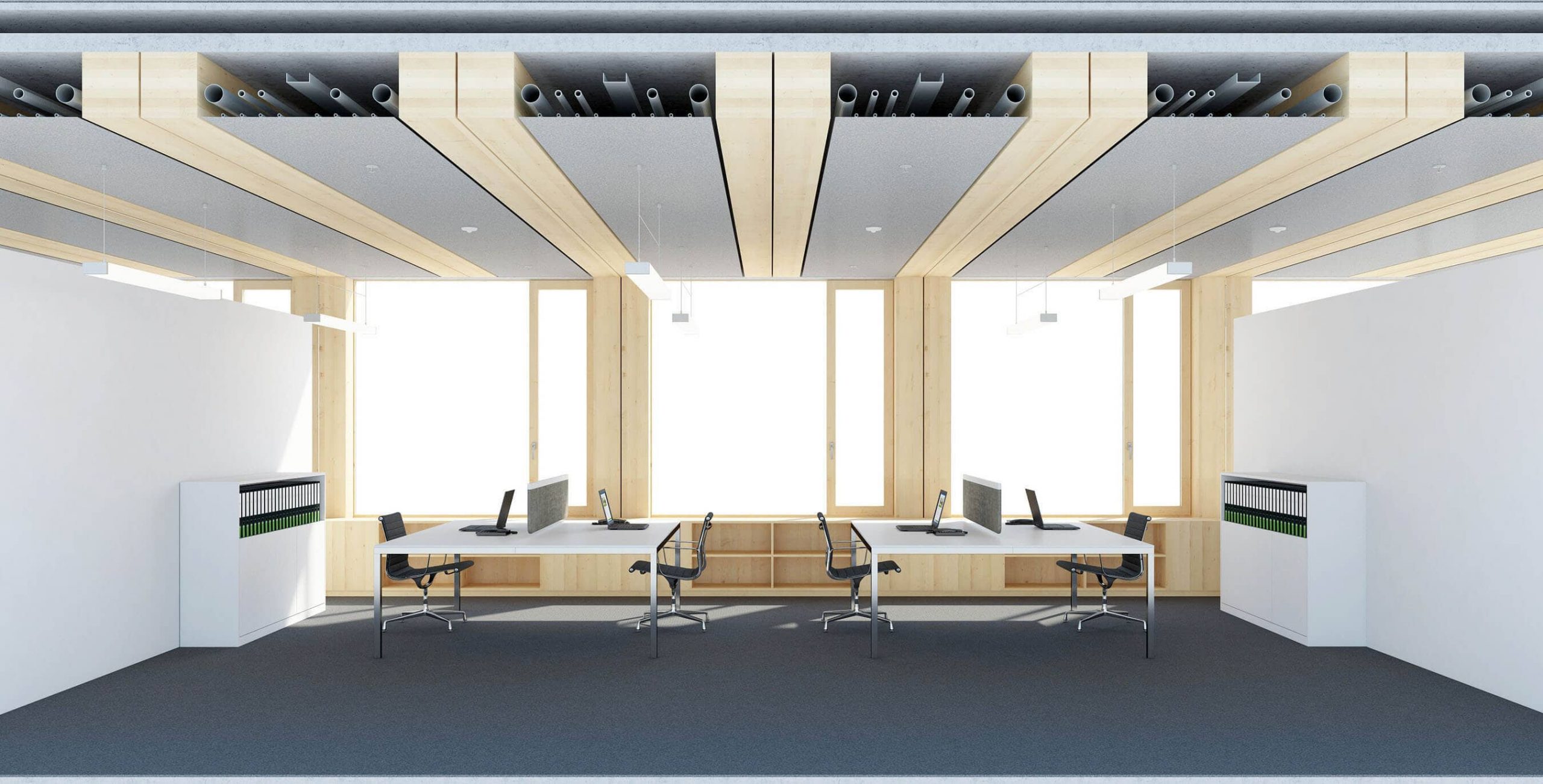

MEP engineering projects involve creating the design plan as well as maintenance of the structure’s MEP system. All in all, MEP engineering plays a crucial role in commercial, residential, and industrial buildings. Specifically, MEP equipment performs various functions like ventilation, refrigeration, indoor humidity control, supplying hot/ chilled water, and space heating & cooling.

Unfortunately, these pieces of equipment have high space requirements because of the associated ductwork and piping. For that reason, Mechanical design engineers should come up with various options to minimize mechanical spaces occupied by these systems. Simply put, they need to design MEP systems that allow more compact installations.

On the bright side, there are many ways to minimize MEP space in any building. And in this article, we’ll be looking at those practices and tips one by one! Without wasting time, let’s get started!

In most cases, the condenser is the largest individual component of an AC unit in HVAC design. Although these devices are usually placed outdoors, they tend to occupy a lot of space on the walls they’re installed on. This can hinder outdoor circulation, especially when they’re installed on the 1st floor of the building.

In addition, condensers emit a lot of heat during use. Yet the movement of this air may be restricted due to limited outdoor area when the building is close to a wall or another building. As a result, the operational efficiency of the condenser will reduce significantly. At the same time, the outdoor space will become uncomfortable because of the warm air.

Thankfully, you can avoid these issues by installing the condenser on the rooftop. Doing so will allow war air to circulate more freely, and save considerable outdoor space. However, this option will only be practical if the ceiling/ rooftop has enough strength to support the Air condenser’s weight.

Examples of AC units installed on the rooftop/ ceiling in typical industrial and commercial projects include;

2. Use Mini-split systems for small buildings instead of packaged rooftop AC systems

The use of packaged rooftop AC systems allows many air condensers to be consolidated as one unit. However, their ductwork requires a significant amount of space. For that reason, they may not be the best option for small residential or commercial buildings. Instead, mini-split systems are considered the best AC units for such buildings since they provide superior energy efficiency and are simpler to install.

Moreover, mini-split systems are feasible in commercial spaces that are split into multiple zones with independent schedules like open-air shopping malls. But as buildings become larger, the use of rooftop packaged systems will emerge as the best option. That is because they’ll eliminate the need for too many evaporators and compressors required with mini-split units for air conditioning.

3. Install HVAC equipment in free & unused spaces

Installing your MEP equipment in areas that aren’t normally is one of the most viable strategies for minimizing MEP space in any building. A good example of such areas is the roof bulkhead, which is found in most buildings, yet it’s rarely used. Typically, a roof bulkhead offers access to the roof. More notably, it’s mainly used during maintenance and construction. However, the bulkhead is hardly used during actual building operation, making it one of the best places to install your HVAC equipment.

4. Use the same system for indoor heating & cooling

Both the heat pump and air conditioner operate on the same principle known as the refrigeration cycle. However, a heat pump operates in reverse in the sense that it extracts heat from a cooler outdoor environment and utilizes it for water/ space heating. Moreover, some of these heat pumps are reversible, meaning they can consolidate heating and cooling into a single piece of equipment. Upgrading such heat pumps will result in a significant improvement in energy efficiency.

Before you choose a heat pump for your building though, there are certain things you need to consider. That is; SEER (Seasonal Efficiency Ratio) and HSPF (Seasonal Heating Performance Factor). SEER shows the ratio between cooling output and energy input for cold seasons. While HSPF operates under the same concept when the system works for heat.

That aside, the best scenario for upgrading to a heat pump in residential applications is when the buildings use an old AC unit and a resistance heater. Here, the heat pump will consolidate 2 devices into one. At the same time, the HVAC design upgrade will improve energy efficiency in both operation modes.

For industrial facilities, however, the best way to consolidate cooling and heating systems is installing an absorption chiller. That way, the chiller will provide cold water for process and space cooling, while using waste heat from an industrial process/ steam plant to heat the space. Alternatively, you can use a normal compression-based chiller, especially if there is inadequate waste heat.

5. Install boilers close to the roof

As you know, boils that involve the combustion of fuels like natural gas or propane to operate need a chimney to exhaust the flue gasses. More importantly, the chimney must move from the boiler to the uppermost level. Therefore, if the boiler is installed farther from the rooftop, the chimney will have significant space requirements. However, installing the boiler close to the rooftop will reduce the chimney’s distance.

Consequently, you will have more space on each floor that you can use for other things. Better still, this will save the cost of building the chimney. Moreover, this will ensure safer installation by minimizing the risk of emitting flue gasses to indoor spaces.

As an alternative, you can replace the boiler with a piece of heating equipment that doesn’t need a chimney. A good example is a heat pump or an electric resistance heater. Similarly, you can install a solar water heater, which is usually placed on the rooftop, thus saving indoor space.

Final Word

Saving space used by MEP equipment in building projects provides many benefits beyond comfort. As an example, it increases energy efficiency and reduces installation costs. That’s why it’s important to hire a qualified MEP designer and contractor for your MEP engineering project.

At InnoDez Design & Engineering, we’ll ensure that your MEP design is done properly to reduce MEP space in your building. So, feel free to contact us today!

About Author

InnoDez