In the dynamic and ever-evolving world of construction and architecture, the term "structural engineering" holds a position of paramount importance.

Introduction

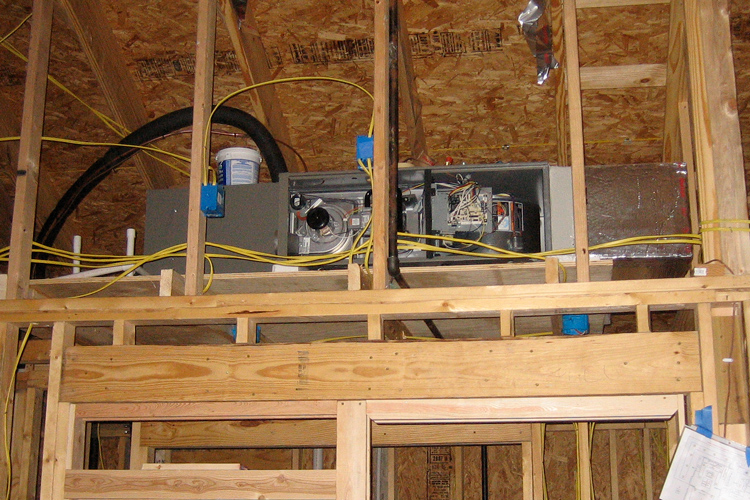

Over the years, building codes, particularly those that relate to energy efficiency have undergone significant improvements. For that, we currently have tested air barriers, more insulation as well as thermal bridging in building enclosures. Similarly, these advancements are significant on the MEP design side. As a result, there is mechanical ventilation as well as reduced duct leakage in airtight buildings.

However, that’s not what we’ll be looking at in this article. Instead, we’ll be looking at what these HVAC design requirements are as suggested by IBC (International Building Codes). First, let’s check out what IBC codes are and how they work!

What is the International Building Code (IBC)?

The IBC (International Building Code) refers to a comprehensive set of standards that address the installation and structural design of building systems. More notably, they apply to various building systems including the Heating, Ventilation, and Air Conditions (HVAC) system design for buildings.

But, how do building codes work? Generally speaking, modal codes are at the highest level. With the ICC (International Code Council) being the major stakeholder in this area. That said, there are 2 codes from the ICC that address HVAC system design requirements for homes. They include; IECC (International Energy Conservation Code) and IRC (International Residential Code). Note, the IRC contains more details on MEP design than the IECC. Moreover, the IECC typically repeats some major HVAC design requirements addressed in the IRC.

That aside, when building a home, you have to meet the HVAC design requirements of the local building department. Fortunately, most local building departments use one of the IBC codes, perhaps with some alterations.

HVAC system design in the IBC (International Building Codes)

Obtaining the building’s cooling and heating loads (manual J) is the first step of duct design in HVAC systems. Then use Manual S to determine the ideal equipment capacity to install. Lastly, design the distribution system for the HVAC unit. If you intend to use an air distribution system, instead of hydronic, it’s important to get the proper air.

The IRC states the following about Duct design in section M1601.1;

Duct systems for HVAC equipment should be installed according to this section’s provisions and

ACCA Manual D. Also, other approved methods including the system manufacturer’s installation guidelines shall be observed.

In addition, the IRC has many other duct design requirements. For instance, it allows the use of joist cavities and studs in floors and walls for return air (M1601.1.1). However, M1601.6 prohibits the garage and living spaces from using the same HVAC system to supply conditioned air.

Both the IECC and the IRC say the same thing on HVAC efficiency rating and equipment sizing. That is; the sizing of cooling and heating equipment shall be done according to the ACCA Manual S. However, this will be done depending on the building load calculations as suggested by approve cooling & heating load calculation n methods like ACCA Manual J.

As for the efficiency, replacement or new HVAC equipment shall have a rating greater or equal to the minimum required by law for the area where the system is installed.

These requirements are addressed in section R403.7 of the IECC and section N1103.7 of the IRC.

Simply put, this requirement states that the sizing of cooling and heating in buildings has to be done per the approved protocols. Those protocols include; the ACCA Manual s for determining the equipment capacity and ACCA manual J for determining the building’s cooling & heating loads.

Airtight building homes require mechanical ventilation, and this has been addressed in IBC as well. To be precise, this requirement is included in section R303.4 (Mechanical ventilation) in the IRC.

Moreover, section N1102.4.1.2 states that a dwelling unit whose air filtration rate is less or equal to 5 air changes/ hour, shall be given the whole-house mechanical ventilation. Section M1505.4 also addresses the same issue.

Interestingly, airtightness requirements proposed by the 2018 and 2015 IECC eliminate the issue of ‘sweet spot’. Instead, the IECC allows the maximum air leakage of 5 ACH50 in climate zones 1 & 2, as well as 3 ACH50 in climate zones 3 (Section R402.4.1.2).

Sections M1505 and N1103.6 in the IRC (International Residential Code) have other ventilation requirements as well. They include;

Final Word

Considering the HVAC design requirements in International Building Codes (IBC) is a good first step. However, local jurisdictions and states including California should adopt these codes, especially the IECC and IRC. Moreover, the IBC code officials should be given enough time and resources to learn and understand these reports. Unfortunately, some officials are not even familiar with the ACCA Manual D, S, and J report. Hopefully, once those issues are addressed, the HVAC design requirements in IBC will be enforced effectively.

About Author

InnoDez