Introduction When it comes to the world of structural engineering, few challenges are as exciting and complex as designing podium

Modern building environments increasingly prioritize energy efficiency, sustainability, and occupant comfort—objectives that MEP (Mechanical, Electrical, and Plumbing) engineering seeks to fulfill through innovative system designs. One of the most effective methods for heating and cooling spaces in commercial and residential buildings is the use of hydronic systems. Hydronic systems use water as the primary heat transfer medium, circulating it through a closed network of pipes, boilers, heat exchangers, and cooling units to distribute thermal energy. This article will dive into the benefits, design principles, and applications of hydronic systems in MEP engineering and examine how firms like InnoDez leverage these systems to meet the unique needs of their clients.

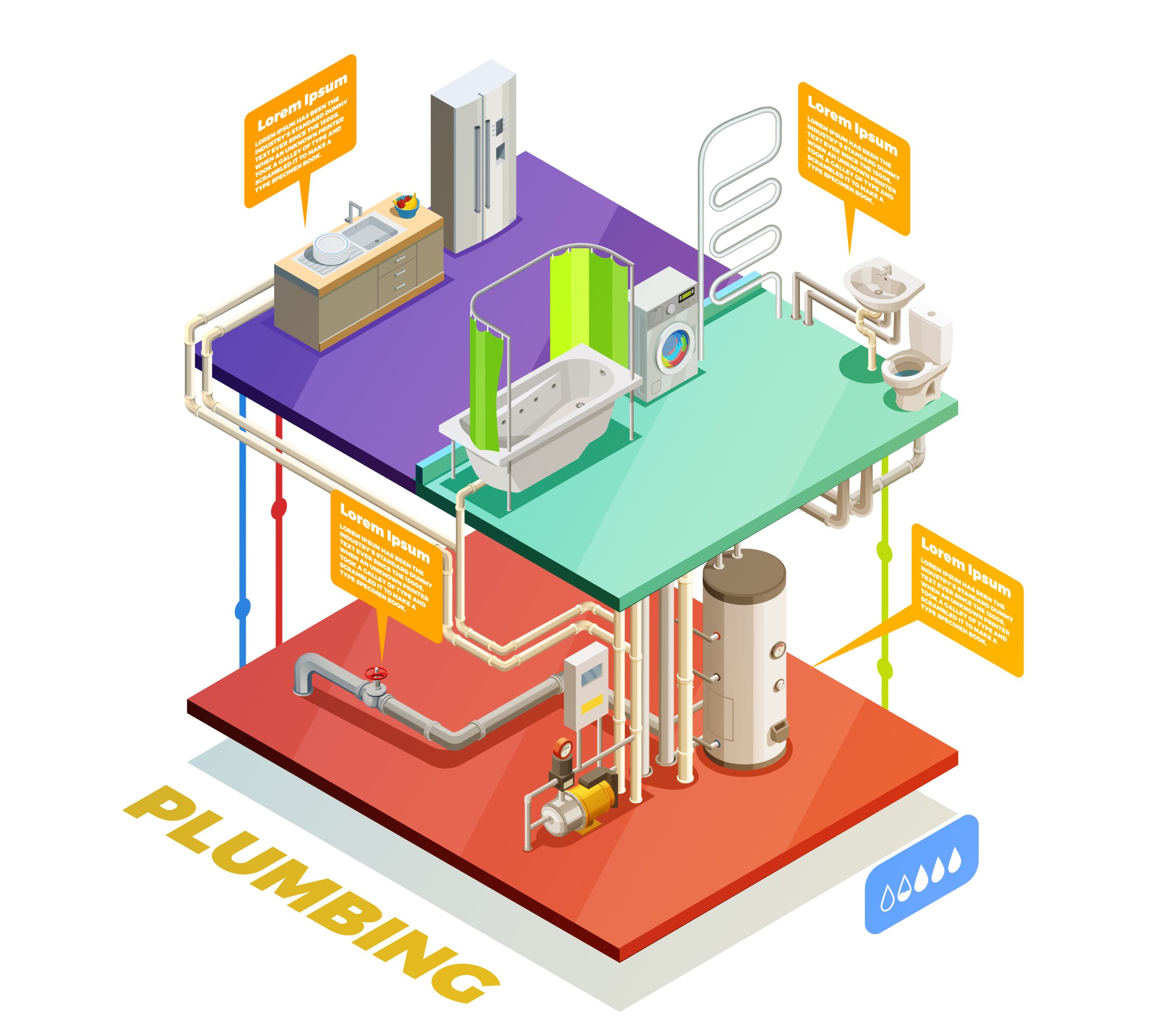

Hydronic systems, sometimes referred to as “wet” or “water-based” systems, use water to transfer heat throughout a building. These systems typically operate on the principles of convection and radiation rather than forced-air methods, providing quieter, more even heating and cooling. Water’s thermal conductivity and storage capacity make it a highly effective medium for temperature regulation, capable of delivering energy savings and environmental benefits.

A hydronic system is typically made up of the following components:

Hydronic systems offer a multitude of benefits over conventional HVAC systems, contributing to their popularity in a wide range of building applications. Here are some of the standout benefits:

Water has a higher heat-carrying capacity than air, meaning it can transport more energy with less volume, reducing the energy required for heating or cooling. By minimizing the energy demands of temperature regulation, hydronic systems can lead to substantial savings on utility bills. This energy efficiency makes them an attractive choice in green building designs and energy-conscious environments. InnoDez integrates hydronic systems to help clients achieve optimal energy efficiency, often incorporating them into LEED-certified building designs to help meet sustainability standards.

Hydronic systems distribute heat more uniformly and gently than forced-air systems, reducing temperature fluctuations. Since they do not rely on blowing air, they also avoid stirring up dust, allergens, and other airborne contaminants, thus enhancing indoor air quality. This quiet and consistent heating and cooling improves occupant comfort, particularly in sensitive environments like hospitals, schools, and luxury residences.

Hydronic systems allow for multiple temperature zones within a single building. With the ability to adjust temperatures in different areas independently, hydronic system provide greater control over indoor environments, improving comfort levels for occupants in various zones of the building. In large facilities, this level of customization is invaluable and can lead to further energy savings.

The lifespan of hydronic system typically exceeds that of forced-air systems, as they contain fewer moving parts prone to wear and tear. Furthermore, water is less corrosive than air, so pipes and other components in hydronic systems tend to require less maintenance and last longer. InnoDez emphasizes the long-term cost savings offered by hydronic systems, particularly for commercial clients who aim to minimize downtime and maintenance expenses.

Designing an efficient hydronic system involves careful planning and consideration of several factors. Here are key design elements that MEP engineers must keep in mind to maximize system performance:

A proper load calculation ensures that the system’s heat source (boiler or chiller) is adequately sized to meet the demands of the building. Overestimating or underestimating load can lead to inefficiencies, higher costs, and occupant discomfort. Load calculations take into account the building’s orientation, insulation, window types, and internal heat gains, providing the basis for designing a well-balanced hydronic system.

In a hydronic system, the distribution network is crucial to efficiently transporting heated or cooled water throughout the building. Proper pipe sizing, insulation, and routing prevent heat loss, maximize energy transfer, and reduce pumping costs. Engineers also consider the use of low-temperature or condensing boilers in hydronic heating systems, which operate efficiently at lower water temperatures and complement radiant floor heating applications.

Zoning enables separate temperature control in various parts of the building, maximizing comfort and efficiency. Each zone may require individual thermostats and actuators, and in some cases, different heat exchangers, depending on usage patterns. InnoDez frequently incorporates smart thermostats and digital controls in its hydronic system designs, allowing for easy monitoring and adjustment across multiple zones, especially in commercial and multi-use buildings.

Hydronic systems can be easily paired with renewable energy sources like solar thermal panels, geothermal heat pumps, and even waste heat recovery systems. Solar thermal energy can be used to preheat water in the system, reducing reliance on fossil fuels and making the system more eco-friendly. Geothermal integration is particularly useful in large commercial applications where underground heat provides a consistent energy source for heating or cooling.

Hydronic systems have versatile applications across various building types, each with unique requirements and challenges. Here’s how they are typically used in residential, commercial, industrial, and specialized settings:

In homes, hydronic heating is commonly installed as radiant floor heating, providing gentle warmth that rises naturally through rooms. This method offers an unobtrusive solution that doesn’t interfere with interior design and furnishings. In multi-family residential buildings, hydronic systems provide central heating and cooling with zoning capabilities, giving residents control over their environments while maintaining energy efficiency.

Commercial applications of hydronic systems span office buildings, hotels, and retail spaces. In office settings, hydronic system provide efficient heating and cooling without the noise of forced-air systems, fostering a comfortable and productive environment. Hotels also benefit from these systems for in-room temperature control and centralized hot water distribution, reducing energy costs and improving guest comfort. InnoDez often recommends hydronic systems for commercial projects aiming to optimize energy use and support high-performance buildings.

In large industrial facilities, hydronic systems are ideal for providing space heating in expansive open areas, which would be challenging and inefficient to heat with forced air. Hydronic heating is also used in process heating applications where precise temperature control is essential. InnoDez’s MEP designs for industrial clients integrate hydronic systems to help achieve reliable and controlled temperature management in both office and operational areas.

Hospitals and laboratories require high air quality and quiet operation. Hydronic systems are highly suitable for such environments because they reduce the spread of contaminants and provide consistent temperature control without excessive noise. Schools and other educational facilities can also benefit from the low-maintenance nature of hydronic systems, which keeps operational costs down while maintaining a comfortable learning environment.

The efficiency of hydronic system depends heavily on factors such as proper system sizing, insulation, and the choice of heat sources. Engineers can implement several strategies to further enhance system efficiency and align with sustainability goals:

Pumps play a key role in moving water throughout the system, and high-efficiency pumps can make a significant difference in reducing energy consumption. Variable-speed pumps that adjust flow rates based on demand are increasingly common, offering substantial energy savings over traditional pumps.

Insulated piping and high-performance materials reduce thermal loss in the distribution network. These considerations are especially critical in buildings where long pipe runs are needed. InnoDez applies top-grade materials and insulation to help clients achieve lasting performance from their hydronic systems.

Water quality directly affects the longevity of a hydronic system. Water treatment minimizes corrosion, scale build-up, and biological growth, which can impair efficiency and shorten the lifespan of equipment. Filtration and chemical treatment systems are common in hydronic installations to keep the system operating at peak efficiency.

Building automation systems (BAS) provide real-time monitoring and control of hydronic system components. A BAS can automatically adjust temperatures, flow rates, and operational hours based on occupancy patterns and ambient conditions, reducing energy waste and improving comfort. InnoDez often integrates hydronic system with BAS in complex projects to allow facility managers greater control and insight into their systems.

Hydronic system continue to play an essential role in MEP engineering, supporting energy efficiency, indoor air quality, and comfort across diverse building types. From residential homes to complex commercial and industrial facilities, these systems offer flexible and durable heating and cooling solutions that align with modern sustainability standards. Firms like InnoDez are at the forefront of designing hydronic systems tailored to the unique needs of each project, bringing together innovative technology, advanced design principles, and energy-efficient practices to create comfortable and resilient spaces.

By optimizing every aspect of hydronic system design, from heat source selection to distribution network planning, MEP engineers can help clients realize long-term savings while minimizing their environmental impact. Hydronic systems are not only a testament to the potential of water-based heating and cooling but also an essential component of the sustainable, efficient buildings of the future.

About Author

Xhuljo Jakup