Are you considering repurposing a building for a new occupancy? If so, you need to be aware of the potential

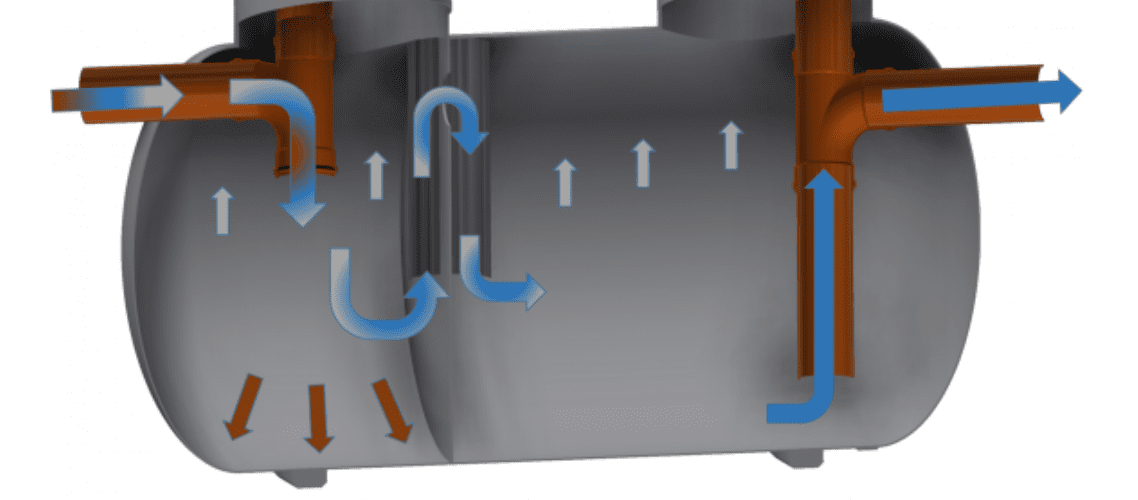

Grease interceptors are essential components of restaurant MEP (mechanical, electrical, and plumbing) systems. They prevent fats, oils, and grease (FOG) from entering the sewer system and causing clogs, backups, and environmental damage. However, traditional grease interceptors have some drawbacks, such as large size, high installation and maintenance costs, and frequent cleaning requirements. In this blog post, we will explore some of the emerging trends and innovative solutions in grease interceptor design that can overcome these challenges and improve the performance and sustainability of restaurant MEP systems. We will also discuss how InnoDez, a leading provider of MEP design and engineering services, can help you implement these solutions in your restaurant projects.

One of the main factors that affect the efficiency and durability of grease interceptors is the material they are made of. Most grease interceptors are made of metal, such as steel or cast iron, which can corrode over time and reduce their effectiveness. Moreover, metal grease interceptors are heavy and bulky, which limits their placement options and increases their installation costs. To address these issues, some manufacturers have developed grease interceptors made of advanced materials, such as fiberglass or plastic. These materials are resistant to corrosion and have a longer lifespan than metal. They are also lighter and more compact, which allows for more flexibility in locating and installing them. For example, some plastic grease interceptors can be installed underground or inside walls, saving valuable floor space and improving the aesthetics of the restaurant.

Another challenge that restaurant owners face with grease interceptors is monitoring and maintaining them properly. Grease interceptors need to be cleaned regularly to prevent FOG accumulation and ensure optimal performance. However, cleaning frequency depends on various factors, such as the size and type of the interceptor, the volume and nature of the wastewater, and the local regulations. Therefore, it can be difficult to determine the optimal cleaning schedule for each interceptor. To solve this problem, some grease interceptor manufacturers have integrated smart monitoring and maintenance technologies into their products. These technologies include sensors, controllers, alarms, and remote access systems that can measure the FOG level in the interceptor, alert the user when it reaches a certain threshold, and even schedule or perform automatic cleaning. These features can help restaurant owners save time and money on grease interceptor maintenance, as well as avoid potential fines or penalties for violating sewer codes.

By adopting innovative approaches to grease interceptor design, restaurant owners can benefit from several advantages for their MEP systems. Some of these advantages are: – Improved efficiency: Innovative grease interceptors can capture more FOG from the wastewater and reduce the risk of sewer blockages and overflows. This can improve the efficiency of the plumbing system and prevent costly repairs or replacements. – Enhanced sustainability: Innovative grease interceptors can reduce the environmental impact of FOG disposal by minimizing the amount of FOG that enters the sewer system or by enabling its recovery and reuse as a biofuel. This can enhance the sustainability of the restaurant MEP system and contribute to its green credentials. – Increased compliance: Innovative grease interceptors can help restaurant owners comply with the local codes and regulations regarding FOG management and disposal. This can increase their compliance rate and avoid potential fines or penalties.

If you are looking for a reliable partner to help you with grease interceptor design for your restaurant projects, look no further than InnoDez. We are a professional MEP design and engineering company that specializes in restaurant MEP systems. We have extensive experience and expertise in designing and installing innovative grease interceptors that suit your specific needs and preferences. We can help you select the best type, size, material, location, and configuration of grease interceptors for your restaurant project. We can also help you integrate smart monitoring and maintenance technologies into your grease interceptor system to optimize its performance and sustainability. Moreover, we can ensure that your grease interceptor system meets all the relevant codes and standards for FOG management and disposal. At InnoDez, we are committed to delivering high-quality MEP design and engineering services that exceed your expectations. We use advanced tools and software to create accurate and detailed MEP drawings and models for your restaurant project. We also provide comprehensive MEP coordination services to ensure that your grease interceptor system is compatible with other MEP systems in your project. Furthermore, we offer competitive pricing and fast turnaround times for our services. If you are interested in working with us on your restaurant project, please contact us today. We would love to hear from you and discuss how we can help you with your grease interceptor design needs.

About Author

InnoDez