How does 3D laser scanning work? 3D laser scanning is a revolutionary technology that has transformed the way we approach

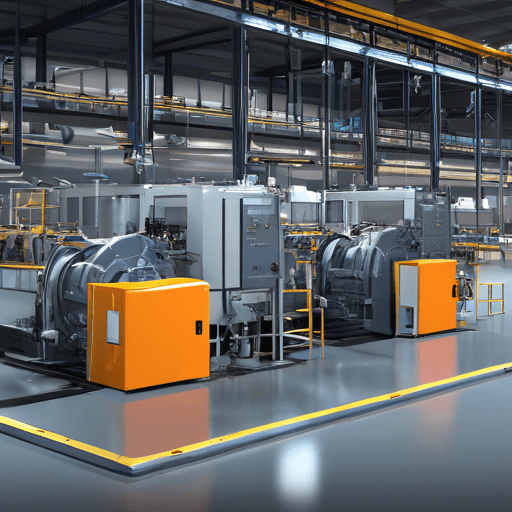

Welcome to the world of manufacturing marvels! In today’s competitive landscape, efficient and safe production facilities are key to success. That’s where MEP (Mechanical, Electrical, and Plumbing) strategies come in. From optimizing workflow to enhancing energy efficiency and ensuring workplace safety, these strategies are revolutionizing the manufacturing industry through MEP Engineering for Manufacturing.

With the rapid advancement of technology, manufacturers are constantly seeking innovative ways to streamline their production processes. By integrating cutting-edge MEP Engineering for Manufacturing strategies, businesses can minimize downtime, reduce operational costs, and maximize productivity. Whether it’s the implementation of smart automation systems or the use of energy-efficient equipment, these strategies help create a seamless and sustainable manufacturing environment.

Ensuring safety is another critical aspect of MEP Engineering for Manufacturing. From fire protection systems to ventilation and air quality control, manufacturers must prioritize the well-being of their employees and the integrity of their facilities. By adhering to comprehensive safety guidelines and investing in state-of-the-art MEP infrastructure, companies can minimize risks and create a secure workplace for their workforce.

Importance of Efficiency and Safety in Production Facilities

Efficiency and safety are paramount in production facilities. In today’s fast-paced world, businesses cannot afford to overlook the importance of optimizing their processes and ensuring the well-being of their employees. Efficient production not only leads to cost savings but also improves overall productivity. Similarly, a safe working environment is essential for employee satisfaction and retention. MEP Engineering for Manufacturing plays a crucial role in achieving these goals by integrating innovative solutions that enhance both efficiency and safety.

Manufacturing facilities face a myriad of challenges, including increasing operational costs, stringent regulatory requirements, and the need to stay competitive in the market. By implementing effective MEP Engineering for Manufacturing strategies, companies can address these challenges head-on. From reducing energy consumption to implementing proactive maintenance measures, MEP systems offer a holistic approach to improving the overall performance of production facilities. This proactive approach not only reduces downtime but also enhances the longevity of equipment and infrastructure.

Understanding MEP systems is key to unlocking their full potential. Mechanical systems encompass heating, ventilation, and air conditioning (HVAC), which are vital for maintaining a comfortable working environment. Electrical systems involve power distribution, lighting, and control systems, essential for powering machinery and equipment. Plumbing systems include water supply, drainage, and fire protection, crucial for ensuring a safe and functional facility. By combining these systems cohesively, manufacturers can create an optimized and sustainable production environment with MEP Engineering for Manufacturing.

Common Challenges in Manufacturing Facilities

Manufacturing facilities often grapple with a range of challenges that hinder their efficiency and safety. One common issue is outdated equipment and infrastructure, which can lead to inefficiencies and safety hazards. Another challenge is the lack of proper maintenance practices, resulting in unexpected breakdowns and costly repairs. Additionally, compliance with ever-evolving regulations poses a challenge for many manufacturers, requiring them to stay abreast of changing standards and guidelines.

Inefficient workflow processes can also impact the overall productivity of a manufacturing facility. Bottlenecks in production lines, poor inventory management, and inadequate resource allocation can hamper efficiency and increase operational costs. Moreover, workplace safety is a top priority for manufacturers, given the potential risks associated with operating heavy machinery and handling hazardous materials. Addressing these challenges requires a strategic approach that combines innovative MEP Engineering for Manufacturing strategies with proactive maintenance and continuous improvement initiatives.

To overcome these challenges, manufacturers must embrace a culture of innovation and continuous improvement. By adopting modern MEP Engineering for Manufacturing solutions, such as smart automation systems and energy-efficient technologies, companies can optimize their production processes and enhance workplace safety. Investing in training programs for employees to familiarize them with new technologies and safety protocols is also crucial for successful implementation. By tackling challenges head-on and leveraging MEP Engineering for Manufacturing strategies effectively, manufacturing facilities can stay ahead of the curve and achieve sustainable growth.

Understanding MEP (Mechanical, Electrical, and Plumbing) Systems

MEP systems are the backbone of modern manufacturing facilities, encompassing a wide range of components that are essential for efficient and safe operations. Mechanical systems include HVAC systems, which regulate temperature and air quality, ensuring a comfortable working environment for employees. Electrical systems power machinery and equipment, providing the necessary energy for production processes. Plumbing systems, on the other hand, ensure the availability of water supply, proper drainage, and fire protection measures. Integrating these components effectively is a core aspect of MEP Engineering for Manufacturing.

Key Components of Efficient and Safe MEP Strategies

Efficient and safe MEP strategies rely on a combination of key components that work together to optimize production facilities. Energy-efficient solutions play a crucial role in reducing operational costs and minimizing environmental impact. By incorporating technologies such as LED lighting, solar panels, and energy management systems, manufacturers can significantly lower their energy consumption and carbon footprint. These solutions not only benefit the bottom line but also demonstrate a commitment to sustainability. MEP Engineering for Manufacturing ensures these energy-efficient solutions are seamlessly integrated.

Enhancing Safety Measures Through MEP Strategies

Safety is a top priority in manufacturing facilities, where the well-being of employees and the integrity of assets are paramount. MEP Engineering for Manufacturing enhances safety measures by incorporating features such as fire detection and suppression systems, emergency lighting, and ventilation controls. These systems not only mitigate risks but also ensure compliance with regulatory standards and industry best practices. By proactively addressing safety concerns, manufacturers can create a secure working environment that promotes employee well-being and operational resilience.

Benefits of Investing in MEP Strategies for Production Facilities

The benefits of investing in MEP Engineering for Manufacturing strategies for production facilities are manifold. From cost savings and improved productivity to enhanced safety and sustainability, these strategies offer a range of advantages for manufacturers. By optimizing energy usage and reducing waste, companies can lower their operational expenses and bolster their bottom line. Additionally, by prioritizing safety measures and compliance, manufacturers can create a resilient workplace that protects both employees and assets. Overall, investing in MEP Engineering for Manufacturing is a strategic decision that yields long-term benefits and positions companies for success in a competitive market.

Conclusion: The Future of MEP Strategies in Manufacturing

In conclusion, MEP Engineering for Manufacturing is indispensable for creating efficient and safe production facilities in the manufacturing industry. By leveraging the latest technologies and best practices in mechanical, electrical, and plumbing systems, manufacturers can optimize their operations, enhance workplace safety, and achieve sustainable growth. As the industry continues to evolve, embracing innovative MEP Engineering for Manufacturing solutions will be key to staying ahead of the competition and meeting the demands of a rapidly changing market. By investing in MEP Engineering for Manufacturing, companies can unlock the full potential of their production facilities and pave the way for a successful future in manufacturing. Join the manufacturing marvels revolution today and transform your facility into a beacon of efficiency and safety!

About Author

Xhuljo Jakup