Introduction In today’s ever-evolving world, energy efficiency and water conservation have become paramount concerns for both businesses and individuals. With

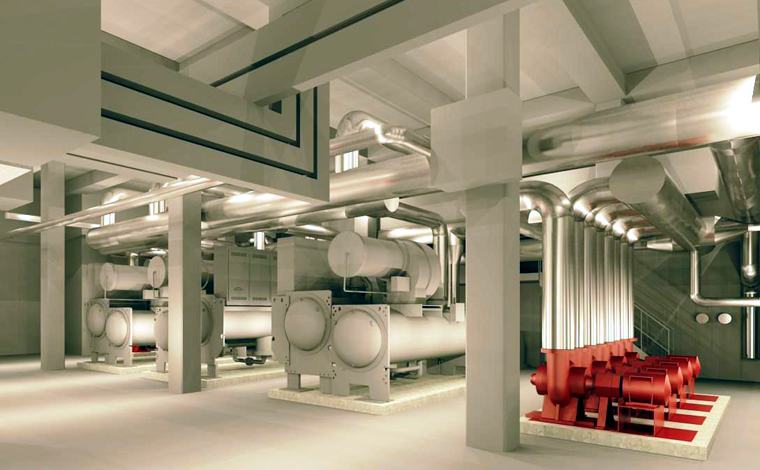

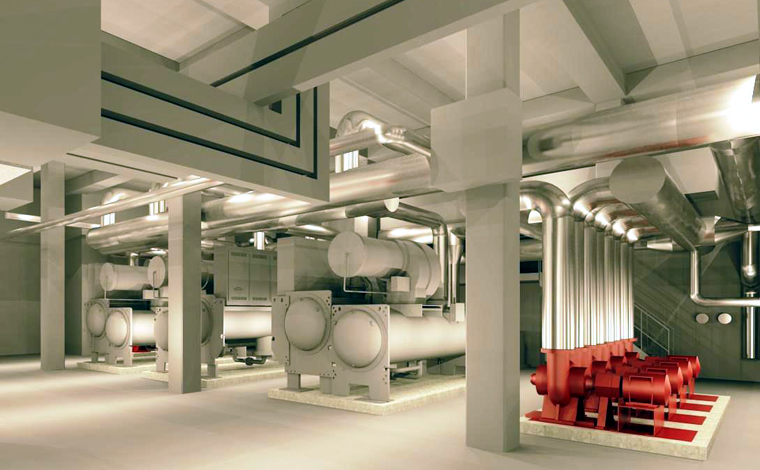

There is no doubt that chillers are first-class things. In many offices, they are one of the most costly bits of hardware. They additionally are the single greatest clients of power in those offices. Ergo, the importance of chiller replacement design is paramount.

Consolidate these components with a chiller’s somewhat long help life of 20-25 years, and it is straightforward why designing and upkeep chiefs move warily with regards to settling on choices on chiller substitution. A few supervisors move too circumspectly, notwithstanding, accepting that up to a chiller is running, it does not merit the cost of supplanting it.

However, these chiefs neglect to comprehend that because a chiller is working doesn’t mean it is working effectively. Also, with working expenses over the existence of a chiller extraordinarily surpassing its underlying expense, supplanting a more established chiller with one that conveys higher effectiveness can incredibly lessen generally speaking power costs.

While diminished working expenses are a solid inspiration to supplant more established chillers, chiefs additionally should weigh different elements, including the chiller’s condition, age and dependability, how building loads have changed, and a chiller’s upkeep necessities. Exclusively by considering the effect chiller substitution can have on these elements would managers be able to decide the genuine benefit of supplanting their offices’ chillers.

Numerous more established outward chillers have full-load working efficiencies of 0.80-0.90 kW/ton, expecting they are in acceptable working condition and have been all around keeping up with. Inadequately kept up with chillers will have a lot of lower working efficiencies.

Conversely, the majority of the present new high-effectiveness chillers have a full-load proficiency of around 0.50 kW/ton. All the more critically, new chillers have higher part-load efficiencies than more established chillers. What’s more, with most chillers working 95% of the time or more under part-load conditions, working on full-burden and part-load working efficiencies converted into critical energy cost investment funds.

To precisely assess energy reserve funds that would be delivered by supplanting a current chiller, directors should foster a heap profile for the current chiller. A heap profile distinguishes a chiller’s energy use in kW/ton over the whole working reach for that chiller in that office, from full-burden to the base burden the chiller encounters.

Furnished with this data, a supervisor can contrast that heap profile with the maker’s heap profile for the substitution chiller. By knowing the number of hours a chiller works at each heap, supervisors can measure the subsequent energy investment funds for chiller replacement design.

Structures today are in a consistent condition of motion. Inhabitants and activities change, as do structures themselves. On the off chance that a chiller was introduced even as late as 10 years prior, odds are the office and its cooling loads are far unexpected today in comparison to when the chiller started the activity.

By and large, these progressions in loads result in a critical oversizing of the current chiller, especially if the association has updated the HVAC frameworks and envelope to further develop energy productivity.

Oversizing a chiller brings about diminished yearly working effectiveness. While introducing a variable-recurrence drive (VFD) will further develop part load productivity, it is more proficient to appropriately coordinate with the size of the chiller to the cooling load.

Supervisors can do this by inspecting the heap profile for the structure, deciding the greatest cooling load the chiller should meet, and deciding the number of hours out of each year that heap happens. While chiefs should hold some extra limit with regards to future office changes, killing oversizing will work on yearly working effectiveness.

A larger than average chiller only occasionally is an adequate justification for supplanting a chiller, yet it is a significant factor to think about while assessing chiller choices for chiller replacement design.

All structure chillers require progressing booked and breakdown support. And keeping in mind that main minor contrasts exist at the expense of most planned support necessities for chillers of a similar kind and size, unscheduled upkeep and fix costs shift generally, in any event, for a similar model chiller.

Similarly as significant as immediate upkeep costs are circuitous expenses related to interferences of administration coming about because of chiller breakdowns. So it is significant that directors lead a careful condition appraisal of the chiller.

Start by going through the chiller’s working log for something like two years to measure costs related to chiller upkeep. Distinguish administration interferences that happened as the consequence of breakdowns or unscheduled support, and gauge the expense of those interferences to the activity.

Give specific consideration to warm exchanger tubes. Have experts whirlpool current-test all chiller cylinders to decide whether any have been harmed. Survey working logs to decide the upkeep history of the cylinders. If various cylinders have required fixing or stopping, it is a negative reflection on the chiller’s general condition and working productivity and chiller replacement design.

About Author

InnoDez