Advancements in Smart Grids As the world becomes increasingly interconnected and technology-driven, the role of electrical engineering in buildings is

Variable refrigerant flow (VRF) technology is a type of HVAC system that uses refrigerant as the cooling and heating medium, instead of water or air. VRF systems can provide simultaneous heating and cooling to different zones, as well as precise temperature control and energy efficiency. In this blog post, we will explain the basics of VRF technology, how it works, what are its benefits and challenges, and how it can be integrated into MEP design and engineering.

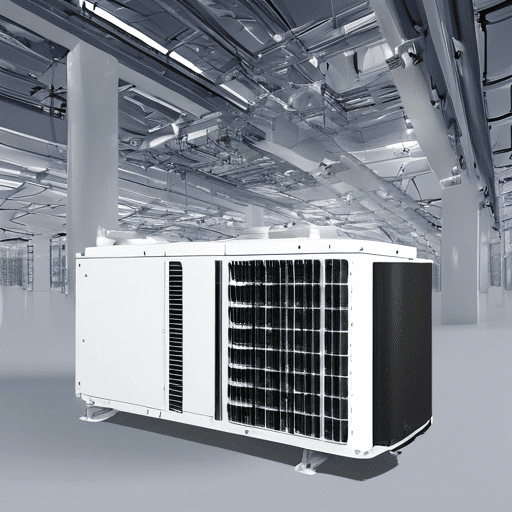

VRF technology is based on the principle of varying the flow of refrigerant according to the cooling or heating demand of each zone. A VRF system consists of three main components:

– An outdoor unit that contains one or more compressors that generate the refrigerant flow.

– Indoor units that are installed in each zone and connect to the outdoor unit via refrigerant piping. The indoor units can be either ducted or ductless, depending on the space and design requirements.

– A control system that regulates the operation of the outdoor and indoor units, as well as the communication between them.

A VRF system can operate in two modes: heat pump mode and heat recovery mode. In heat pump mode, the system can either provide cooling or heating to all zones, but not both at the same time. In heat recovery mode, the system can provide simultaneous cooling and heating to different zones, by transferring heat from one zone to another through a branch controller. This way, the system can recover waste heat and reduce energy consumption.

VRF technology offers several advantages over conventional HVAC systems, such as:

– Energy efficiency: VRF systems can modulate the refrigerant flow according to the load and weather conditions, thus reducing energy waste and operating costs. VRF systems can also recover heat from one zone to another, further improving efficiency and comfort.

– Flexibility: VRF systems can accommodate various building layouts, sizes, and shapes, as well as different occupancy patterns and preferences. VRF systems can also be easily expanded or modified by adding or removing indoor units.

– Comfort: VRF systems can provide precise temperature control and individual zoning, allowing users to adjust the temperature according to their needs and preferences. VRF systems can also reduce noise levels, as the indoor units operate at low fan speeds and the outdoor units are located away from the occupied spaces.

– Reliability: VRF systems have fewer moving parts and less maintenance requirements than conventional HVAC systems, resulting in lower failure rates and longer lifespans.

VRF technology also has some limitations and challenges that need to be considered before choosing it for a project, such as:

– Initial cost: VRF systems have a higher initial cost than conventional HVAC systems, due to the complexity and quantity of components involved. However, this cost can be offset by lower operating and maintenance costs over time.

– Refrigerant management: VRF systems use refrigerant as the cooling and heating medium, which poses environmental and safety risks in case of leaks or accidents. Therefore, VRF systems need to comply with strict codes and standards regarding refrigerant type, quantity, piping, installation, testing, and servicing.

– Integration: VRF systems need to be integrated with other building systems, such as ventilation, fire protection, lighting, security, etc., which requires careful coordination and communication among different disciplines and stakeholders. VRF systems also need to be compatible with the building automation system (BAS) for optimal performance and control.

InnoDez is a design and engineering company that provides MEP design and engineering services for various types of projects, including residential, commercial, industrial, institutional, healthcare, etc. InnoDez has extensive experience and expertise in designing and implementing VRF systems for different applications and scenarios.

InnoDez can help you with:

– Feasibility analysis: InnoDez can evaluate your project’s needs and goals, as well as the site conditions and constraints, to determine if VRF technology is suitable and beneficial for your project.

– System design: InnoDez can design a customized VRF system that meets your project’s specifications, requirements, budget, schedule, etc., using advanced software tools and best practices.

– System commissioning: InnoDez can verify that the VRF system operates as intended and performs according to the design criteria, using proper testing methods and procedures.

If you are interested in VRF technology and want to know more about how InnoDez can help you with your project, please contact us today. We would love to hear from you and discuss your project’s needs and challenges.

About Author

InnoDez