In Florida, vacuum piping design is integral to the efficient operation of various industries, including pharmaceuticals, laboratories, and manufacturing plants. Careful planning and consideration during the design process are paramount to ensure optimal performance and reliability.

Tailored Design Process: Vacuum piping design begins with a meticulous assessment of factors such as required vacuum levels, equipment specifications, and building layout. Tailoring the design to meet the specific needs of each facility ensures optimal functionality and efficiency.

Material Selection and Sizing: Choosing the appropriate materials and sizing the pipes correctly are crucial steps in vacuum piping design. In Florida’s diverse climate, selecting materials that withstand environmental factors such as humidity and temperature fluctuations is essential for long-term durability and performance.

Focus on Efficiency and Reliability: The ultimate goal of vacuum piping design is to create an efficient and reliable system that enhances productivity, improves safety, and reduces operational costs. Proper installation techniques are employed to minimize leaks and maximize performance, ensuring consistent vacuum levels and smooth operation.

Industry-Specific Applications: Vacuum piping systems cater to a wide range of industries in Florida, from pharmaceuticals to manufacturing. By understanding the unique requirements of each sector, engineers can tailor the design to optimize performance and meet industry standards and regulations.

Enhanced Productivity and Safety: A well-designed vacuum piping system enhances productivity by providing consistent vacuum levels for critical processes. Moreover, it improves safety by minimizing the risk of equipment malfunction and ensuring a controlled environment for sensitive operations.

In Florida’s dynamic industrial landscape, optimized vacuum piping design is essential for efficient and reliable operations. By customizing the design process, focusing on material selection and sizing, and prioritizing efficiency and reliability, engineers can create vacuum systems that meet the diverse needs of industries across the state, ensuring enhanced productivity, safety, and cost-effectiveness.

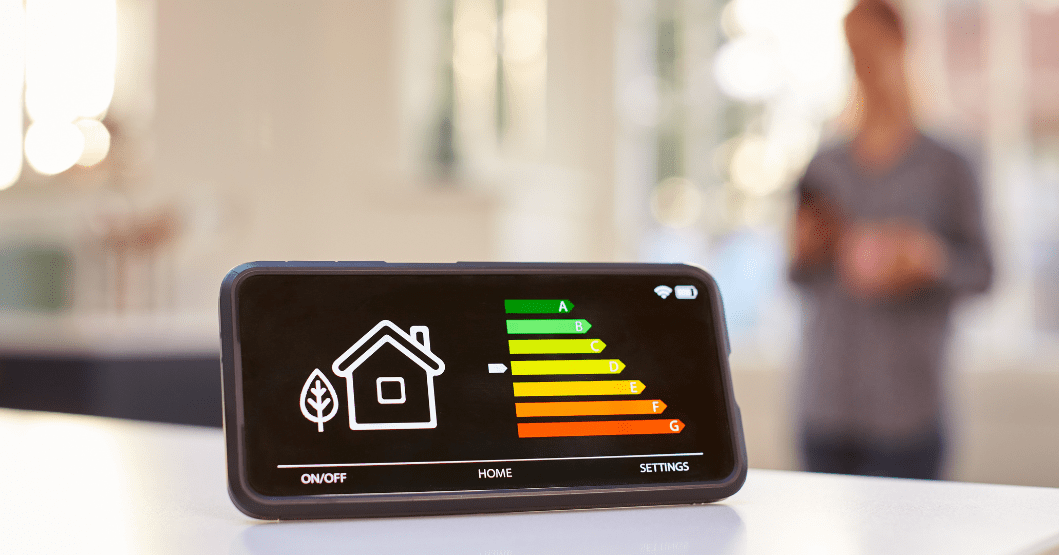

Mechanical Systems: HVAC (Heating, Ventilation, and Air Conditioning) systems form the backbone of a building’s mechanical infrastructure. Our team carefully analyzes cooling and heating loads, ventilation requirements, and energy efficiency to design HVAC systems that provide optimal comfort while minimizing energy consumption.

Mechanical Systems: HVAC (Heating, Ventilation, and Air Conditioning) systems form the backbone of a building’s mechanical infrastructure. Our team carefully analyzes cooling and heating loads, ventilation requirements, and energy efficiency to design HVAC systems that provide optimal comfort while minimizing energy consumption. Electrical Systems: From lighting design to power distribution, our expert engineers have the knowledge and experience to create efficient electrical systems. We consider factors such as electrical load calculations, lighting controls, backup power solutions, and sustainable energy options to ensure your project operates safely and reliably.

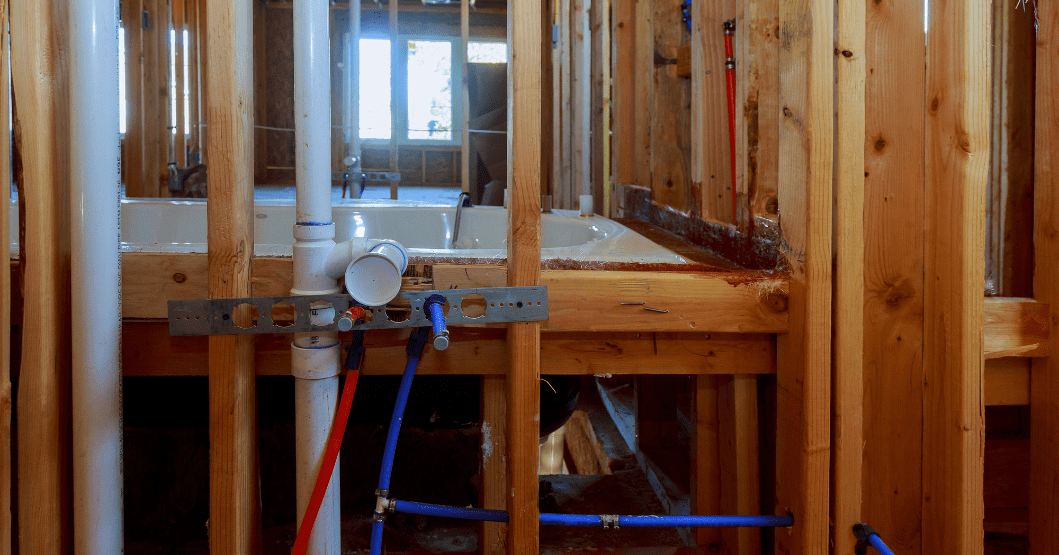

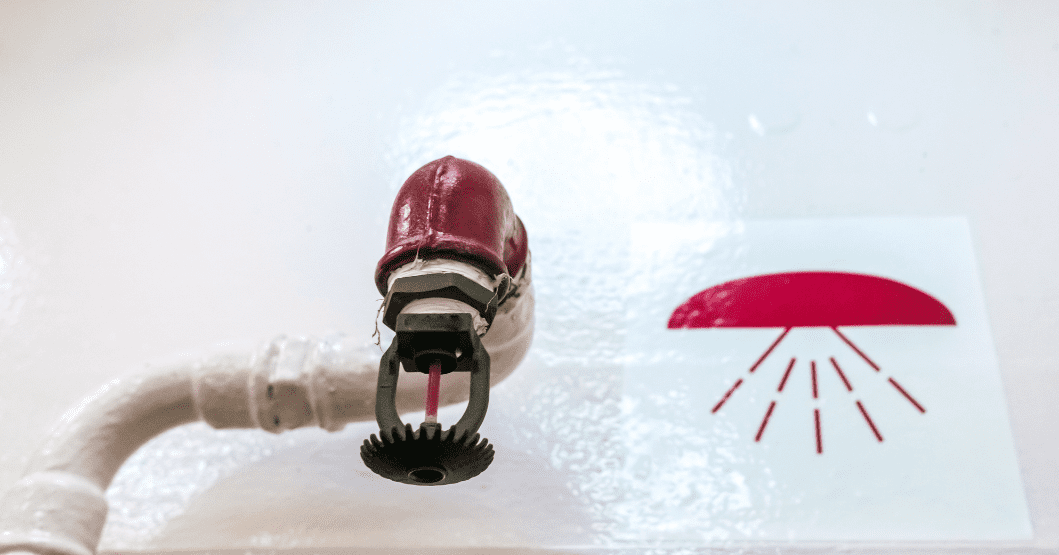

Electrical Systems: From lighting design to power distribution, our expert engineers have the knowledge and experience to create efficient electrical systems. We consider factors such as electrical load calculations, lighting controls, backup power solutions, and sustainable energy options to ensure your project operates safely and reliably. Plumbing Systems: Plumbing design is essential for proper water supply, waste removal, and fire protection in any building. Our team utilizes advanced techniques to design plumbing systems that conserve water, prevent leaks, and adhere to stringent health and safety standards.

Plumbing Systems: Plumbing design is essential for proper water supply, waste removal, and fire protection in any building. Our team utilizes advanced techniques to design plumbing systems that conserve water, prevent leaks, and adhere to stringent health and safety standards.