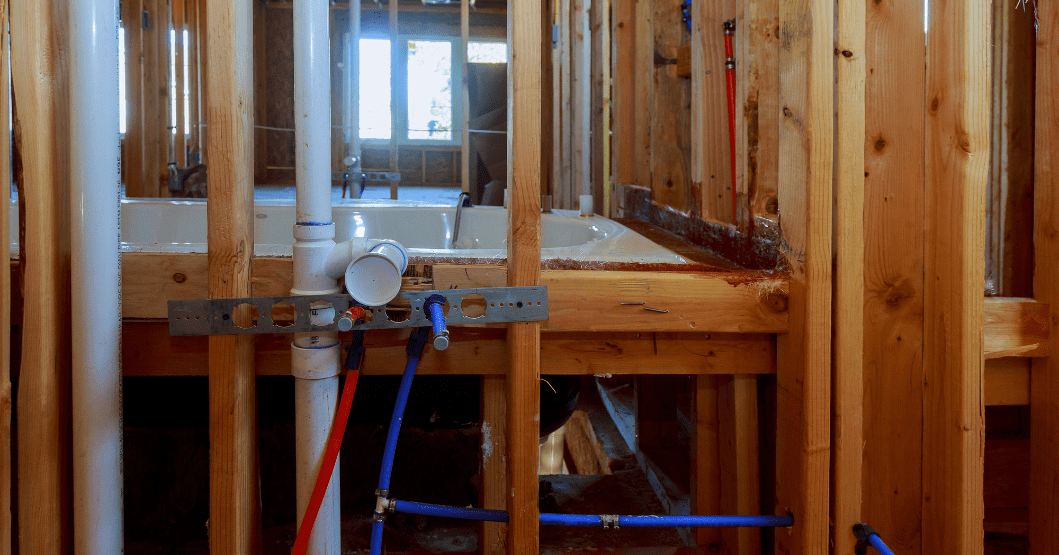

Water services schematics play a crucial role in the design, installation, and maintenance of water systems in Texas buildings. These schematics provide a detailed representation of the layout and configuration of the plumbing and water supply systems, including the location of pipes, valves, pumps, and other components, as well as their sizes and connections. Water services schematics are essential for ensuring that the water distribution system functions efficiently and meets the requirements of building occupants.

One of the primary benefits of water services schematics is that they allow for proper planning and coordination during the construction phase. By having a detailed representation of the water system, architects, engineers, and contractors can work together to ensure that all components are properly integrated into the building design. This helps to minimize errors, reduce rework, and improve overall project efficiency.

In Texas, where building codes and regulations can be stringent, accurate schematics ensure compliance with local standards. This is particularly important given the state’s unique climate and occasional water scarcity issues, which necessitate efficient and reliable water systems.

In addition to aiding in the construction process, water services schematics also serve as a valuable reference for ongoing maintenance and troubleshooting. With a clear visual representation of the system, maintenance personnel can quickly identify and locate components, making repairs and replacements more efficient. This helps to minimize downtime and ensure that the water supply remains uninterrupted.

Overall, water services schematics are an integral part of any building project involving water distribution systems in Texas. They provide a detailed representation of the system layout, aiding in planning, coordination, and maintenance. By utilizing these schematics, professionals can ensure that water services are designed and installed to meet the needs of building occupants while adhering to industry standards and regulations.

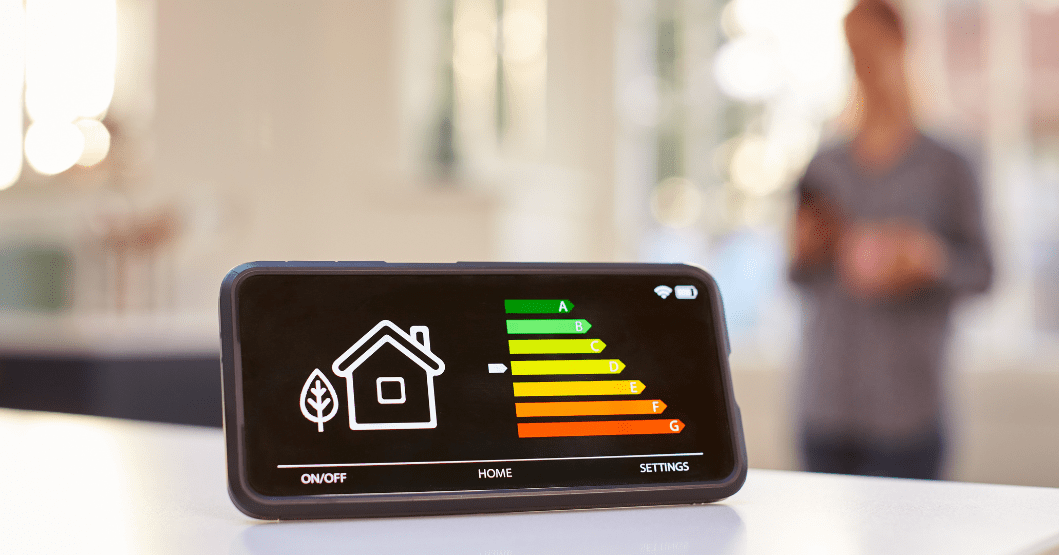

Mechanical Systems: HVAC (Heating, Ventilation, and Air Conditioning) systems form the backbone of a building’s mechanical infrastructure. Our team carefully analyzes cooling and heating loads, ventilation requirements, and energy efficiency to design HVAC systems that provide optimal comfort while minimizing energy consumption.

Mechanical Systems: HVAC (Heating, Ventilation, and Air Conditioning) systems form the backbone of a building’s mechanical infrastructure. Our team carefully analyzes cooling and heating loads, ventilation requirements, and energy efficiency to design HVAC systems that provide optimal comfort while minimizing energy consumption. Electrical Systems: From lighting design to power distribution, our expert engineers have the knowledge and experience to create efficient electrical systems. We consider factors such as electrical load calculations, lighting controls, backup power solutions, and sustainable energy options to ensure your project operates safely and reliably.

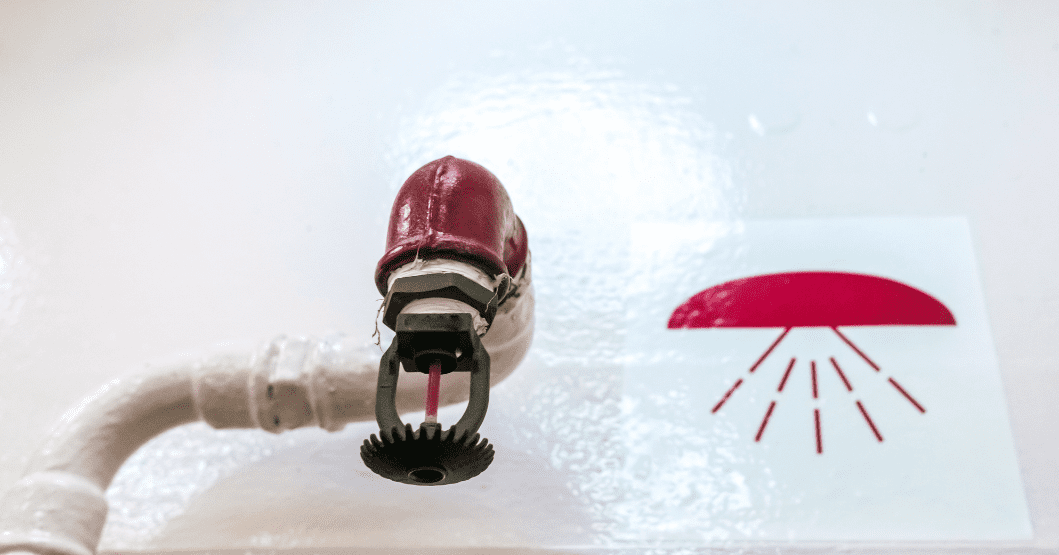

Electrical Systems: From lighting design to power distribution, our expert engineers have the knowledge and experience to create efficient electrical systems. We consider factors such as electrical load calculations, lighting controls, backup power solutions, and sustainable energy options to ensure your project operates safely and reliably. Plumbing Systems: Plumbing design is essential for proper water supply, waste removal, and fire protection in any building. Our team utilizes advanced techniques to design plumbing systems that conserve water, prevent leaks, and adhere to stringent health and safety standards.

Plumbing Systems: Plumbing design is essential for proper water supply, waste removal, and fire protection in any building. Our team utilizes advanced techniques to design plumbing systems that conserve water, prevent leaks, and adhere to stringent health and safety standards.